The Last Drone Standing

The U.S. Department of Commerce issued a challenge to drone manufacturers. The purpose was to compete in a First Responder Unmanned Aircraft System (UAS) Endurance Challenge. This competition would find the best drone technology to help extend the flight time for drones that carry heavy payloads.

Existing technology in modern-day drones frequently can’t provide adequate support to first responders. The equipment package necessary is too heavy for drones to carry for very long.

Overall, 43 teams entered the competition in which the participants would design, build, and flight test a UAS for 90 minutes. The UAS was to carry a 10-lb communications device that would provide broadband coverage in an area lacking adequate communications bandwidth, for as long as the system could function properly to transfer critical data files to the first responders.

The big challenges were weight restrictions, vertical takeoff and landing (VTOL), an ignition kill system, and an appropriate fuel system. And all of this must ensure cost-effectiveness.

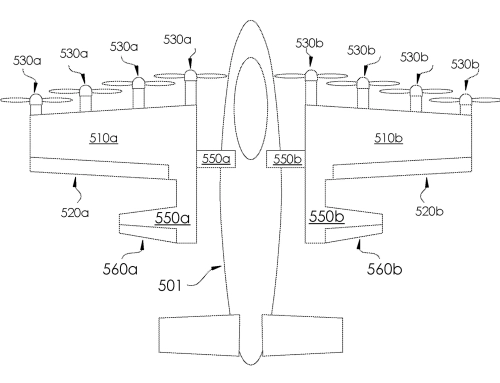

The top prize went to Team Advanced Aircraft Company (AAC), a veteran-owned company making American-made drones, whose entry was a six-rotor drone with propellers on each of the six arms. Power was provided by a hybrid-electric propulsion system that significantly improved energy density over batteries, enabling longer flight times.

Their flight time in this challenge was 112 minutes and 17 seconds. The UAS weighed 29.93 pounds (13.58 kilograms), the lightest one in the competition.

Original Article: https://www.electronicdesign.com/technologies/power/whitepaper/21249044/electronic-design-power-density-key-to-drone-uav-endurance